In 3D printing processes, there are many thermal stress related defects that can have a significant negative impact on the shape

and size of the structure. Such anomalies in the heat transfer of the printing process need to be detected at an early stage.

Understanding heat transfer is crucial, and simulationmodels can offer insightswhile reducing the need for costly experiments.

Traditional numerical solvers for heat transfer can be complex to adapt to diverse printed part geometries, and their reliance on

predefined mathematical models limits their flexibility. Our physics-informed deep learning (PIDL) approach eliminates the

need for discretization, simplifying the analysis of complex geometries and enabling automation. The drawback of parametric

PIDL is their scalability for high-dimensional problems. Computational time, energy and cost of training prevent real-time

analysis. It often takes only a few seconds to print a single layer.We can show an energy efficient transfer and training strategy

to reduce the computational effort of PIDL significantly. The approach is able to quantify relevant effects of thermal stresses

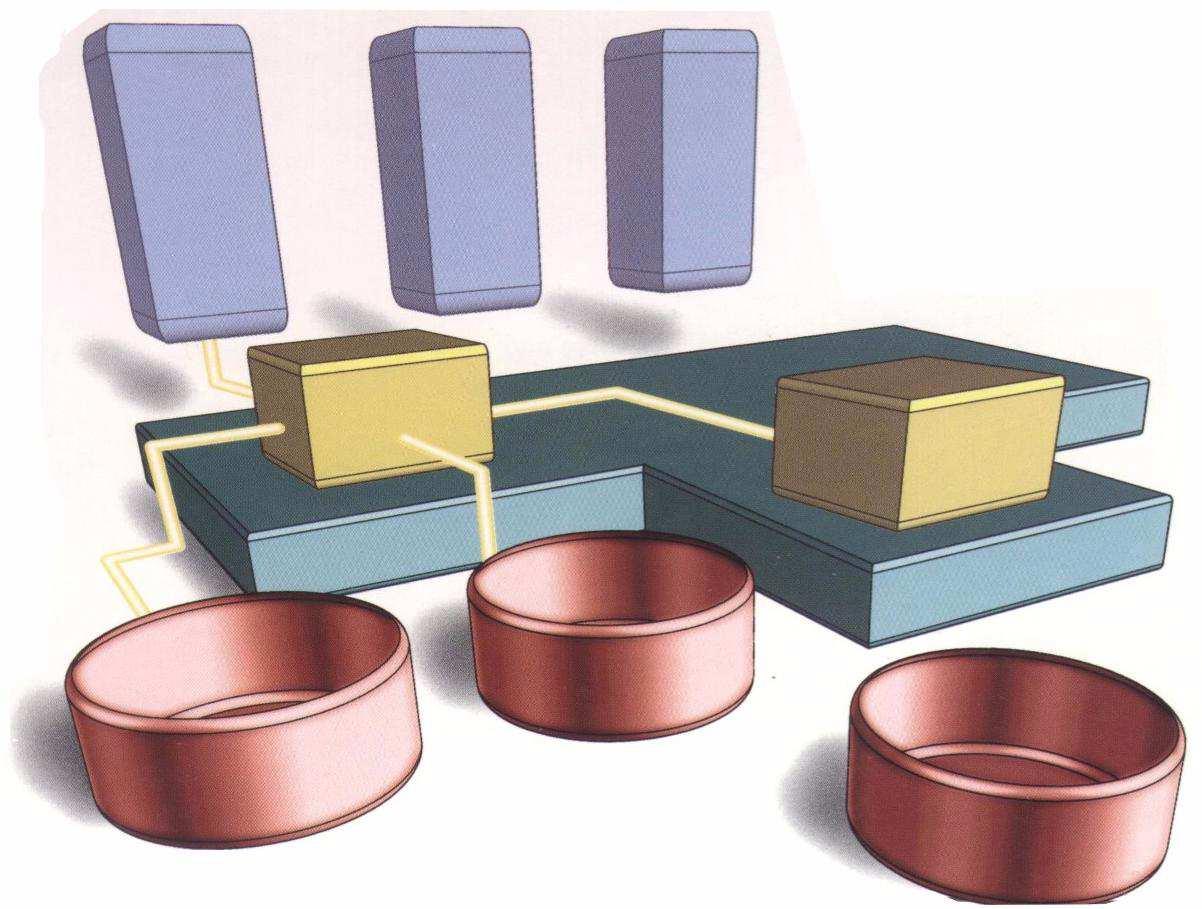

and mitigate errors during selective laser melting (SLM). To this end, heat transfer is modelled, simulated and analysed using

high-dimensional data obtained from printing experiments with different geometries of metal components. The proposed

method is applied to the solving forward problem of heat transfer prediction. The governing results are based on the heat

equation, which is integrated into a deep neural network (DNN).